Breaking the Price Myth in High-Cost Markets

“That’s just what it costs here.”

We hear this all the time from realtors and contractors in luxury markets. But, that story props up an outdated system - one where inefficiency, limited labor, and logistical challenges give license to local builders to inflate costs without improving outcomes. We believe there’s a better way.

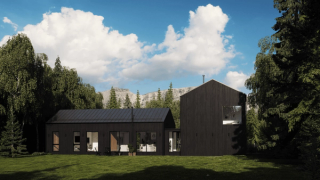

At HUTS, we’ve designed and developed properties in some of the most notoriously expensive markets in the country—Martha’s Vineyard, Sun Valley, the islands of the Penobscot Bay, The Sea Ranch.

And we’ve done it at build costs well below what many would consider possible. How?

First off, we reject the assumption that high-end zip codes automatically demand sky-high construction budgets. Instead, we’ve developed a toolkit that lets us defy those expectations, using smart design, standardized systems, and a mix of local and non-local labor to create homes that are beautiful, well-built, and appropriately priced—even in places where the norm is anything but.

In markets like The Sea Ranch, for example, typical construction pricing can range from $900–$1,200 per square foot. Sun Valley often exceeds $1200/SF. On Martha’s Vineyard, it’s not unusual for clients to get quotes above $1,000/SF. Compare that to national averages, which are still about 30% of that, depending on location and level of finish. The delta is staggering. But, instead of accepting that premium as inevitable, HUTS takes a different path.

How We Do It:

- Design to Construction Standards: Our HUTS Standards are designed to align with American building conventions (16" OC framing, standard material sizes), reducing complexity for any GC and expanding our labor pool.

- Cost-Aware Design: We reverse-engineer from budget, policing scope, and finishes to align with the project’s financial goals—not just the dream wishlist.

- Pre-fab & Panelization: We selectively integrate pre-fab techniques and panelized assemblies to speed up timelines and reduce waste—without sacrificing design integrity.

- Hybrid Labor Model: In high-cost labor markets, we bring in select trades from more affordable regions for specific scopes, while still partnering with trusted local contractors.

- Offsite Coordination: We handle large portions of project management and coordination remotely, saving time and reducing on-site delays.

These aren’t hacks—they’re systems. And they allow us to deliver homes that feel every bit as refined and rooted in place as their $1,000/SF neighbors, at a fraction of the price.

The Bigger Picture: Why This Matters Everywhere

What’s striking is that markets like these—once seen as luxury outliers—are becoming more and more common. Areas from the Hudson Valley to the Rockies are seeing price pressure that mimics long-established luxury enclaves. Construction costs are ballooning in towns that used to be affordable, driven by limited labor pools, material markups, and the rising expectations of buyers.

In other words, the challenges of Martha’s Vineyard are starting to look like the challenges of Main Street. That means the HUTS approach—tight cost control, systemized delivery, flexible trades, and intentional design—isn’t just a clever workaround anymore. It’s becoming a requirement. The era of assuming local crews and blank-check budgets will solve the problem is over. To build the next generation of homes—anywhere—we need new models. HUTS was built for this.