Evolutionary Home Delivery Tactics

Modern home designs for rural destinations. Houses that are better designed, a little smaller, and more affordable than what's out there. Ordered from and delivered by a sleek, branded company with a unique perspective on supply chain. Built with the help of a distributed network of skilled carpenters and neighbors alike.

Sound familiar? 🤔

A high-growth, disruptive business model? Absolutely.

Contemporary? Not exactly.

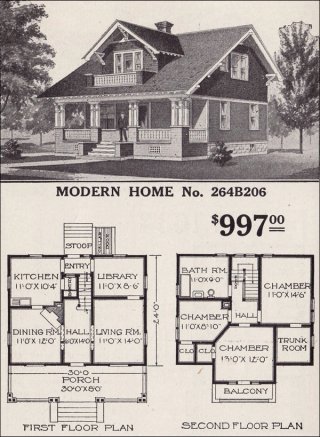

This is the service description and value proposition from Sears & Roebuck in 1923 at the peak of their Sears Modern Home offering. This century-old approach successfully resulted in 70,000 home builds in the US between 1908 and 1940. It's also one of the genetic lineages that the HUTS body of services was born from.

Sure, the static printed catalog has been replaced by an ever-evolving website. Painted billboards have been replaced by dynamic, targeted online ads (...and, uh, more billboards). Building science has leapt forward, making the original Sears homes look like leaky buckets compared to an air-tight, high-efficiency HUTS home.

But, even after 100 years, a couple of important ideas bind HUTS to Sears' innovative approach to home delivery many generations ago.

#1: Designing for Common Knowledge & Decentralized Production

In the early 20th century, the average rural resident had some skills. They knew how to use a saw, manage some basic plumbing, and electric was more or less optional. Sears geared their house designs and construction methodology to that common knowledge base, making sure that every buyer could, conceivably, build what they ordered.

At HUTS, we're under zero illusion that all of our customers could (or should) build a house themselves. Our customers are dentists, lawyers, painters, store owners, and all manner of things that don't necessarily prepare you to turn a pile of wood, wires and tubes into a house. At least, not a good one.

What we do focus on, however, is how to simplify our details. And standardize those details for today’s distributed workforce of rural homebuilders: the individual GC and small-scale home building operations.

There is a common base of knowledge among qualified rural contractors across the country. They know wood framing. They know poured concrete foundations. They know how to work well with standard-sized elements - for windows, doors, roof panels, decking and siding - even when the assemblage of those elements is far more architecturally considered.

At HUTS, we spent an enormous amount of time and treasure matching our Standards to the skills that we identified as common among contractors and home builders across the country. We tailored our products to make sure that the types of GCs we partner with can successfully build your most valuable asset.

#2: The Intrinsic Value of Participation

Sears understood that participation in the process creates a sense of pride in buyers and imbues the product with greater perceived value. In the case of Sears homes, that participation happened both in the build process and through the inevitable design customizations homeowners made once the kit of parts started to look more like an assembled home.

A lot of companies have tapped into the importance of selective participation. Ikea gets it. Even Nike, through NikeID (and recently rebranded as “Nike by You”), understands the psychology behind it. Every single human has a design perspective and making something one’s own creates a deeper sense of value.

Does everyone want to do all of the design?

No, they want a base in place. Less of a brand new creation from a blank page, more of an edit to a draft that’s pretty close to right. A starting point to make customizations to, but with thoughtful limits on the amount and scale of customization that can be made.

Let’s take the Nike by You example. I don't really know how shoes are made and don’t have the skills or ambition to reinvent what a shoe is. But, I know exactly what color ways and patterns work for my wardrobe. Give me some guardrails to make it my own, but don’t let me make something that’s worse off than where it started.

Or think of Ikea. Studies suggest that people value things they make more than things they buy. For better or worse, Ikea has ridden this bit of human insight about as far as one could imagine, turning particle board sheets into treasured objects. Some of the most proud moments people share on social media come from their successfully-completed Ikea hack.

While Nike’s production is morally questionable and Ikea’s environmental impact is pretty atrocious, they have both managed to fold their customers into the process, and turn so-so products into something more precious.

At HUTS, we ask what if we started with a truly excellent product. We call our products Standards. Sustainable and responsible in its sourcing approach. Thoughtful and considered in its design, function and aesthetics. Tested and vetted in the real world.

And, then we brought in just the right amount of client participation to tailor the home to their lifestyle, without blowing up the underlying building systems. Can we create a product with a real sense of craft? A predictable process of delivery that creates unique, individual homes?